The concept of Hydrodynamic Cavitation

|

|

|

|

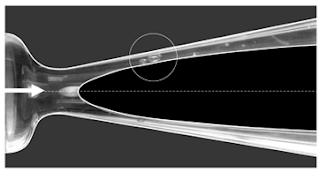

At low

flowrate, water is everywhere free of cavitation. Velocity is maximum in the

section of minimum area and pressure is then minimum.

When the

flow rate is progressively increased, the minimum pressure decreases and

there will be a critical flowrate for which the vapour pressure is obtained

at the throat.

At this

operating point, cavitation appears in the section of minimum area. In Figure,

two bubbles are clearly visible in the upper part of the Venturi. This is the

start of the cavitation state.

|

If the flow

rate through the Venturi is further increased, the extent of cavitation

increases.

At this

point the chlorine when injected will oxidise the organic matter in exploded

bubble and due to the large surface area available, the oxidation by chlorine

molecule is almost instantaneous.

|

ü

There is no limitation on the levels of TDS

concentration. Generally Biological systems cannot accept TDS concentration

> 8000 mg/L

ü

Any concentration of Ammoniacal nitrogen and phenolic

compounds can be treated.

ü

It has got a very small foot print. GIDC handed over

the plant of 5.5 MLD covering an area of 5.5 Acres. Now we are able to increase

the treatment capacity of CETP to 20 MLD in the same premises using the

technology of hydrodynamic cavitation.

ü

The treatment is carried out at ambient temperature

and slight pump pressure

ü

The time required is about 6 ~ 8 hours (can be

adjusted to suit the conditions) where as in biological treatment the aeration

tanks are designed for 4-5 days (96 ~ 120 hrs)

residence time

ü

Existing units can be used with slight modifications

to incorporate this system

ü

Cost of treatment is very low (0.08-0.14 Rs/L)

compared to MEE where the cost is in excess of Rs. 2.5/L (Rs. 2.5 to 6.5 per

Liter)

ü

The treated wastewater is like sea water with TDS

Concentration of 25,000 to 35,000 mg/L, which will be subjected to recycle by Reverse

Osmosis or Water Generation technology of Alfa Laval

ü

The Sludge generated from the hydrodynamic cavitation

based treatment is sent to the Cement Industries for Co-processing as it

contains CaO (70 ~ 80%)